Pelletizing Die Plates Manufacturer in India | Maxwell

Pelletizing die plate are essential components in plastic pelletizing systems, as they dictate the shape, size, and uniformity...

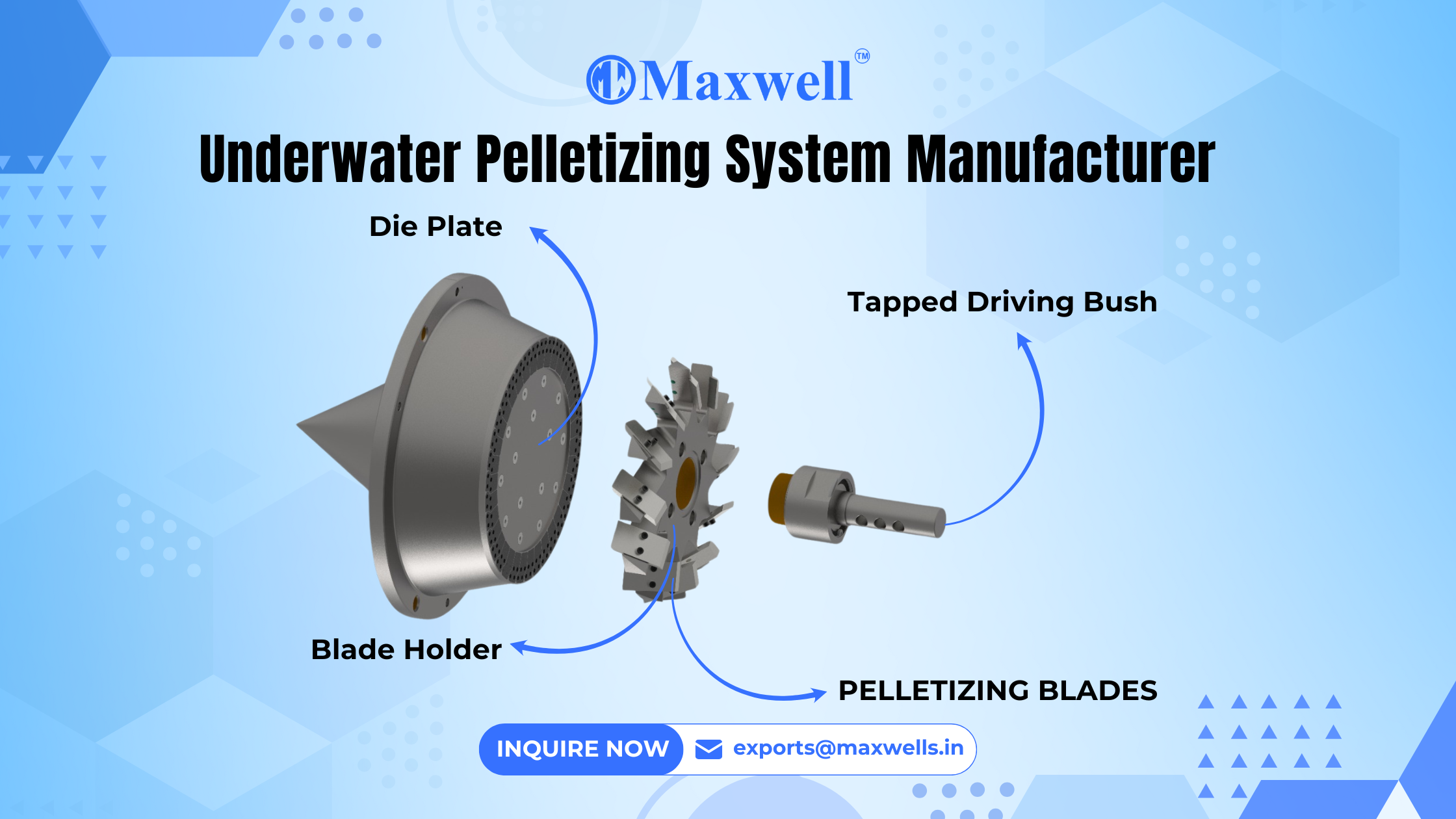

An underwater pelletizing system refers to a method of pelletizing where molten polymer is directly cut into pellets at the die face while submerged in water. The pellets are rapidly cooled and solidified, leading to a highly uniform shape and size of the pellets.

Maxwell, a reputable underwater pelletizing system manufacturer in India, creates and provides precise pelletizing systems to satisfy the expanding needs of the PET recycling, polymer compounding, and plastic manufacturing sectors.

An underwater pelletizing system is a pelletizing method in which molten polymer is cut into pellets directly at the die face under water. The pellets are rapidly cooled and solidified, leading to a highly uniform shape and size of the pellets.

In contrast to conventional strand pelletizing, this system removes the issues of strand breakage and the need for manual handling, rendering it suitable for continuous and high-capacity production lines.

Systems for underwater pelletizing are frequently utilized for:

The underwater pelletizing process consists of a meticulously regulated sequence:

At Maxwell, every component is designed to guarantee consistent cutting performance, extended service life, and minimal downtime.

Selecting an underwater pelletizing system provides numerous operational and quality advantages:

These benefits render underwater pelletizing the favored choice for contemporary recycling and compounding facilities.

The underwater pelletizing systems produced by Maxwell are utilized in various industries:

Each system is tailored according to the type of material, the capacity of output, and the requirements of the process.

Maxwell is a trusted name in pelletizing solutions, providing cutting-edge engineering and manufacturing expertise. Our strengths encompass:

As an experienced underwater pelletizing system manufacturer in India, Maxwell provides solutions that enable customers to attain consistent output and operational excellence.

The recycling of PET necessitates consistent processing and uniformity in pellet quality.

Underwater pelletizing systems are particularly well-suited for PET because of:

Maxwell creates pelletizing systems that facilitate efficient and sustainable operations for PET recycling.

Pelletizing die plate are essential components in plastic pelletizing systems, as they dictate the shape, size, and uniformity...

Maxwell Engineering Solutions proudly participated in the PRS India Exhibition, presenting our latest innovations in underwater pelletizing components...

Maxwell Engineering Solutions proudly participated in the PRS India Exhibition, presenting our latest innovations in underwater pelletizing components...