About this Feature

Maxwell Engineering Solutions PackMachWorld Magazine feature marks an important milestone for the company as it continues to gain global recognition in the polymer processing and packaging industry. Being featured in PackMachWorld, one of the most respected industrial magazines, highlights Maxwell’s reputation for engineering excellence, technical reliability, and innovation in pelletizing technology.

PackMachWorld Magazine is widely read by engineers, plant managers, decision-makers, and investors across the world. It showcases companies that are pushing the boundaries of industrial performance through advanced design and practical solutions. Maxwell Engineering Solutions Ltd. was selected for its ability to deliver high-precision underwater pelletizing systems that help manufacturers achieve better output, improved quality, and stable long-term operation.

Why Maxwell Engineering Solutions Was Featured in PackMachWorld Magazine

The editorial team at PackMachWorld focuses on organizations that create measurable value in real-world manufacturing environments. Maxwell Engineering Solutions was featured because of its consistent success in building pelletizing systems that perform reliably under demanding production conditions.

The magazine article explains how Maxwell’s engineering philosophy is based on accuracy, durability, and deep understanding of polymer processing. By combining modern CNC machining, advanced materials, and practical field experience, Maxwell produces equipment that supports a wide range of applications, including PE, PP, PET, and engineering plastics.

Understanding Underwater Pelletizing Technology

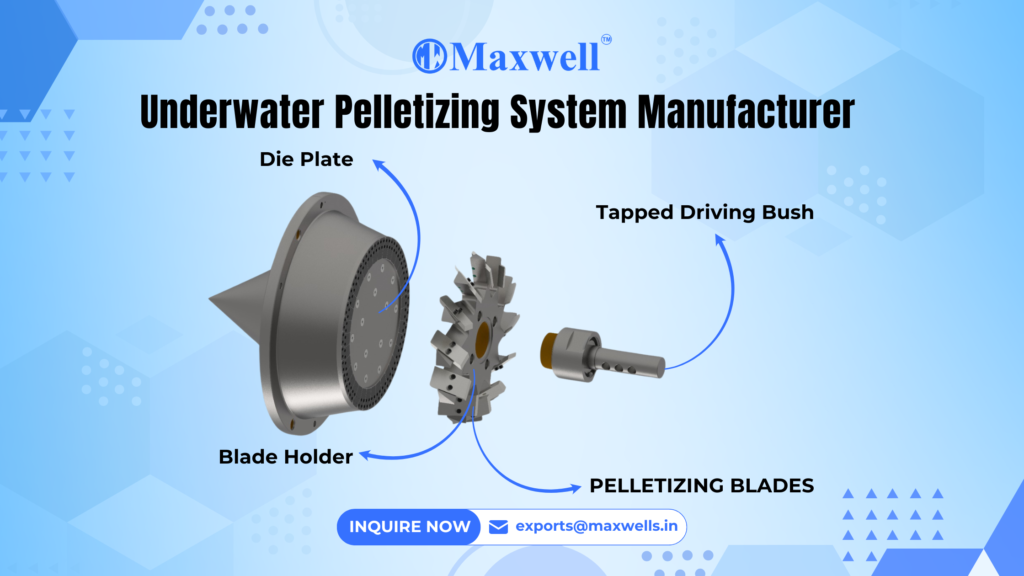

A major focus of the Maxwell Engineering Solutions PackMachWorld Magazine feature is underwater pelletizing. This technology plays a crucial role in modern polymer processing where higher throughput and consistent pellet quality are essential.

In underwater pelletizing, molten polymer is cut into pellets directly inside a water chamber. This allows the pellets to be cooled instantly and uniformly, resulting in smoother surfaces, better shape, and tighter size control. Compared to traditional strand pelletizing, this method offers greater stability, especially at high production speeds.

For recycling and compounding applications, where material quality can vary, underwater pelletizing provides the consistency needed to keep production running without interruptions.

Precision Engineering That Delivers Real Results

The PackMachWorld Magazine article highlights the importance of precision engineering in Maxwell’s pelletizing systems. Every component, from the die plate and cutter hub to the water chamber and drive mechanism, is designed to work in perfect alignment.

This precise coordination allows the system to maintain stable cutting and cooling even when output levels change. Over time, this results in better pellet uniformity, reduced equipment wear, and lower maintenance costs. These advantages are especially important for manufacturers who run continuous production lines and require dependable performance.

Supporting High-Performance Polymer Production

Today’s polymer processors face increasing pressure to produce more material while maintaining strict quality standards. The Maxwell Engineering Solutions PackMachWorld Magazine feature explains how underwater pelletizing helps manufacturers meet these challenges.

By delivering consistent pellet quality at higher throughputs, Maxwell’s systems allow producers to improve efficiency without sacrificing stability. This is particularly valuable in PET recycling and compounding operations, where fluctuations in feedstock can otherwise disrupt production.

Maxwell’s technology helps ensure that pellets remain uniform, which improves downstream processes such as drying, conveying, and molding.

Global Recognition Through PackMachWorld Magazine

Being featured in PackMachWorld Magazine places Maxwell Engineering Solutions among the leading technology providers in the packaging and polymer processing industry. The magazine is a trusted source of information for industry professionals around the world, making this feature a strong endorsement of Maxwell’s capabilities.

For customers, this recognition confirms that Maxwell’s technology meets international expectations for quality and performance. For partners and stakeholders, it demonstrates the company’s continued growth and commitment to engineering excellence.

Read the Original PackMachWorld Magazine Feature

Below you can view the original Maxwell Engineering Solutions PackMachWorld Magazine article exactly as published. This allows you to explore the full feature and see how Maxwell’s underwater pelletizing technology has been presented to the global industry audience.

Read the Original PackMachWorld Magazine Feature

In practice, most PET recycling plants don’t choose a pelletizing method based on theory alone. The decision usually comes down to what keeps running smoothly once the line is under load. Compared with strand pelletizing, underwater pelletizing tends to handle higher outputs with fewer interruptions, especially when automation is part of the setup.

Pellet quality is another factor that becomes more noticeable over time. At higher throughputs, small variations in cooling or cutting can quickly show up downstream. For PET recycling, underwater pelletizing is often selected not because it is the simplest option, but because it remains stable when operating conditions are less predictable.

Source: PackMachWorld Magazine – Vol. 24, Issue 4 (Oct–Dec 2025)

Publisher: PackMachWorld

Featured Company: Maxwell Engineering Solutions Ltd.

Topic: Precision Underwater Pelletizing Technology